Essential tool to improve productivity and efficiency in your production of DTF and UV DTF production.

No more scissors, but a clean cut and an efficient production to increase your sales volume at a reasonable cost. A safe investment quickly amortized.

- Automatic XY cutter in 65cm – 26″ width.

- Table top model. An optional stand is available as an option.

- Cheaper and more efficient than a flat bed cutter for this type of work.

- Minimum width cut sizes 2cm – 0,8″.

- A Roxy cutter can support several printers or can be set online with higher capacity printers with the retrofitable swing arm option.

- A low investment for a fluid production.

- Cut done with or without cut marks.

- Applications : DTF, DTF UV, coupe de bobines en feuilles, étiquettes.

Cut sheet collectionin a metal drawer with a magnetic divider, to separate the sheets and the off-cut marks.

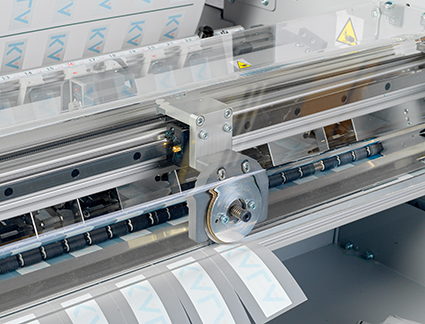

Vertical cutting blades

Economical blade holder, easy and fast to adjust to cut most of the printing materials.

Rotary blade, self sharpening for the horizontal cuts.

A sensor detects the marks and the media advance is driven by the electronic of the machine.

LA PRODUCTIVITE AVANT TOUT AVEC CES OPTIONS

On line Kit

Swing arm to monitor the advanceo of the media through the cutter,

adjusting to the printing speed automatically.

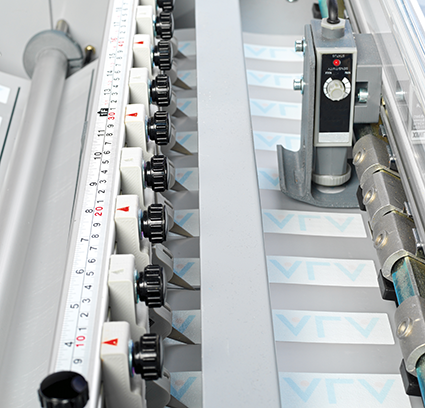

Y Blade holding bar

Y blades are supported on a graduated bar for a fast and easy positionning. This bar can be removed easily from its support for quick tool changes during production.

This bar and the blades are available as an option.

A bar can be fitted for usual working size, without needing to remove and adjust the blade position each time when changing cutting sizes.

Simple and efficient!

Y Blade adjusting set

Graduated tray for storing and adjusting the position of the vertical cutting blades.